Health and Safety Policies: COSHH

In this Health and Safety Policy article we are going to be taking a look at COSHH and what you need to do to make it a part of your Health and Safety Policy.

What is COSHH?

COSHH stands for the Control of Substances Hazardous to Health. More specifically in this article we will be talking about the Control of Substances Hazardous to Health Regulations 2002. It is the law that requires employers to control substances that are hazardous to health.

It’s important to note that asbestos does not fall under COSHH; asbestos is governed by its own set of regulations.

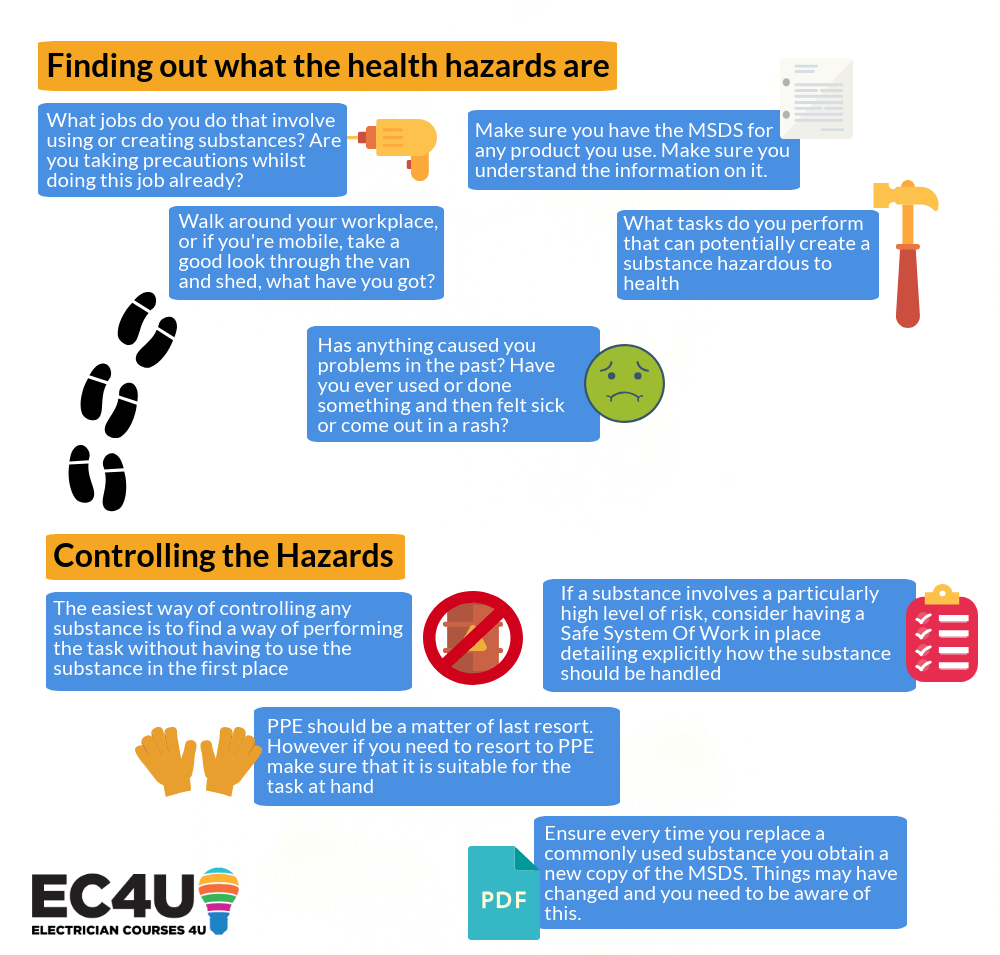

COSHH is a relatively simple concept to get your head around – the main aim of it is to identify any substances that you either use during your work, or substances that can be created during work, and whether that substance is any way harmful to your health.

The HSE provides guidance on determining what the hazards are and how to control them.

Material Safety Data Sheets

Any product or substance that you use should come with what’s known as a Material Safety Data Sheet or MSDS for short. This sheet should contain information on the potential hazards of the material, i.e. its affect on health, its flammability, its affect on the environment and its reactivity. A lot of substances that you can buy off a shelf won’t necessarily have a physical copy of their MSDS’s with them; however, it is very easy to get the MSDS of the substance in a pdf document from the manufacturers’ website. This sheet should be printed out and kept in a dedicated COSHH file that makes up part of your Health and Safety Policy. MSDS can seem a bit overwhelming at first as they contain a lot of information. The HSE has a handy tool, the COSHH e-tool, which helps you perform an assessment of the substance using its MSDS if you are unsure of any of the information contained in it.

Having an MSDS is all well and good for substances that you can buy off the shelf, but there will be substances you either create or encounter during your work that this approach won’t work for; the dust that is created when drilling or chasing masonry for example. Some guidance can be found via the HSE’s website under the ‘industries’ section whilst trade magazines can provide useful guidance and awareness about these sorts of substances as well.

Risk Assessment

Once you have identified all the substances that you either use or encounter, and have documented them, the next step is to identify the risk they may pose; this can be done by performing a Risk Assessment. The outcome of your risk assessment should determine what the next step is.

If the substance has been highlighted as particularly high risk, the first thing you should consider is, is there a safer alternative that can be used? Or maybe there’s a way of performing the task without having to resort to using the substance in the first place. It’s important to think it through logically.

If there is no alternative to using the substance then ensure you have read and understood the control measures that will be listed on the MSDS, this will include things like exposure limits and time scales and what Personal Protective Equipment (PPE) should be used.

Examples of Substances Covered by COSHH

There can be a lot more to COSHH, but generally as a domestic Electrician you’re not going to be using, or exposed to some of the nastier substances out there.

A quick look through our COSHH cupboard and the MSDS of some of the items in there reveals:

Intumescent sealant – MSDS states no adverse risks or harm to the user

Resin jointing compound – This one is a little more interesting, it states that the product may cause skin irritation, serious eye irritation and may cause respiratory irritation. In the event of using it, gloves and eye protection would be a sensible precaution to take.

Decorators caulk – At first glance you may think that the decorators caulk is fairly harmless, and to a degree you would be correct, close inspection of its MSDS however reveals that if the caulk is going to be used repeatedly or for prolonged periods of time, gloves should be worn.

Cable pulling lubricant – Again this is fairly benign; it only recommends using gloves if you find it necessary, it does however recommend the use of safety glasses or splash goggles to protect eyes however.

WD40 – This has a very comprehensive MSDS, not only recommending the use of gloves and goggles, but also specifying their fit and to what Standard they should be manufactured.

Want to find out more about Health and Safety Policies?

This resource on COSHH is the latest in our series which discusses different aspects of your Health and Safety Policy. Click below to catch up on previous resources: