What you need to know about Portable Appliance Testing

PAT testing is something that most people have heard of but may not be 100% sure of what it is and why it needs to be performed. In this article we are going to be take an in-depth look at the ins and outs of Pat testing and why it’s required.

What is PAT testing?

Portable Appliance Testing is the name given to a series of inspections and electrical tests carried out on portable equipment to ensure that is able to be used safely. It is more accurately known as the Inspection and Testing of In-service Electrical Equipment.

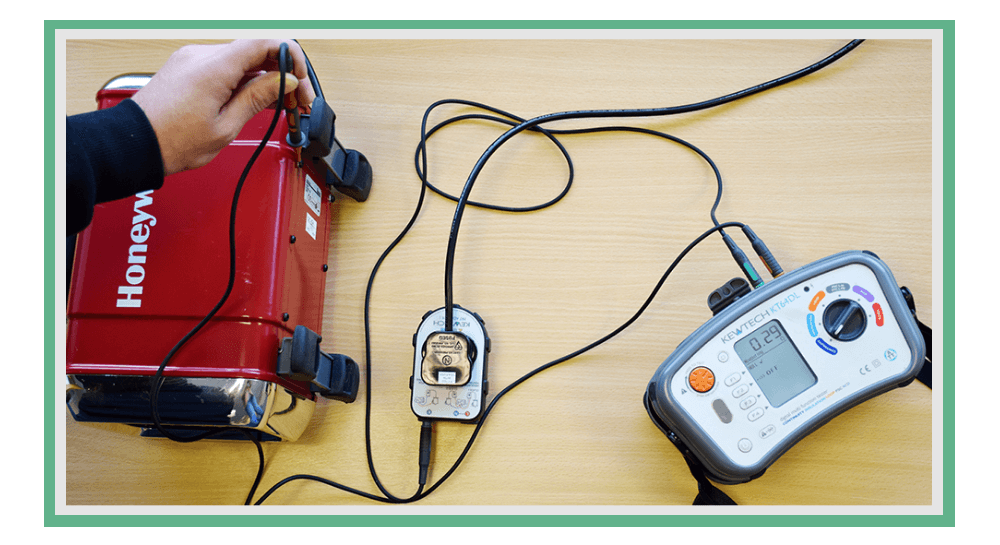

It is important to note that performing a Portable Appliance Test doesn’t just consist of plugging a piece of equipment into a PAT tester and seeing if it passes or fails. Portable Appliance Testing also encompasses the recording and upkeep of records.

We will look at the individual parts that make up a recommended Portable Appliance Test in greater detail further on in this article, based on the guidance given in the IET’s Code of Practice for In-service Inspection and Testing of Electrical Equipment. Firstly though we need to understand why Portable Appliance Testing is important and how it came about.

![]()

There are four main pieces of legislation that are applicable to Portable Appliance Testing; these are the pieces of legislation that essentially gave rise to Portable Appliance Testing in its current form. The first three are:

• The Health and Safety at Work act 1974 – This applies to employees and employers at work and places a duty of care on everyone to ensure their own safety and that of others

• The management of Health and safety at Work Regulations – To ensure that the Health and Safety at Work Act can be implemented properly, every employer has to carry out risk assessments to ensure that employees, and those not in their employ are not subjected to any danger

• The Provision and Use of Work Equipment Regulations 1998 – This ensures that the employer is responsible for supplying equipment that is suitable for the purpose for which it is going to be used

These three pieces of legislation are essentially the driving force behind the need for Portable Appliance Testing. To meet the criteria of the legislation the employer has a duty to ensure any equipment, in this case electrical, that is supplied is safe to use.

![]()

The next piece of legislation is important because it is the driver behind whom and how the Portable Appliance Testing is carried out:

• The Electricity at Work Regulations 1989

There are two very important definitions within theses regulations, which are:

Electrical system – This relates to anything that generates, stores, transmits or uses electricity.

Duty holder – This is anyone who has control of an electrical system. This means if you are working with or testing electrical systems you are deemed to be in control, and hence the Duty holder. As a Duty Holder you have a legal responsibility to ensure the safety of yourselves and others when in control of an electrical system.

Why are these two definitions important? If you are performing a Portable Appliance Test on a piece of electrical equipment, you are the duty holder and you are in control of the electrical system, which means that your safety and everyone else’s is your responsibility.

This then ties into what could be considered the key regulation from the Electricity at Work Regulations which is Regulation 16 – Persons to be competent to prevent danger or injury.

Basically this regulation states that unless you have the correct technical knowledge or experience to perform a task, or are under supervision by someone who does, you should not perform that task if it is likely to cause harm or injury.

So this is essentially saying that unless you have the experience or knowledge to perform a Portable Appliance Test you shouldn’t be doing so.

Technical knowledge and experience

So what is meant by technical experience and knowledge? It is important to note that at this point none of the pieces of legislation looked at mention either specific qualifications or specific roles, i.e. at no point is a qualification such as City and Guild 2377 mentioned and neither is a role such as registered electrician or chartered electrical engineer. This is because it’s recognised that while an individual may hold a qualification or perform in a particular role, it does not mean that the individual is competent in every area that qualification or role may encompass.

Demonstrating competence is however difficult to demonstrate in the majority of situations, which is where formally recognised qualifications come in. As an example, a small business employs 25 people, in their offices is a variety of IT equipment, fan heaters, desk fans etc. The company decides to arrange for one of their employees to perform all their Portable Appliance Testing in house. They don’t however have any one with the correct technical knowledge and experience to perform the testing, they therefore make the decision to send one of their employees on a Portable Appliance Testing course, successful completion of which will give the employee a nationally recognised qualification. Upon completing this course and gaining the qualification the employee has demonstrated to a recognisable level their technical knowledge and experience and could be deemed competent to carry out the testing.

A different example would be that of a Registered Domestic Installer who is with a Part P scheme provider such as the NICEIC. To become registered, they would, as a minimum, already have to have proven their competency both by providing the requisite qualifications and by being assessed in person. This person is in a different situation to the employee spoken about previously. They have already proven that they have the right technical experience and knowledge to design, install and commission new electrical installations in people’s homes, they may not have been specifically trained to perform a Portable Appliance Test, but they already understand the risks and hazards of working with electricity. So would this individual be required to take a Portable Appliance Testing qualification? Not necessarily. This individual is within their rights to perform PAT testing to the guidelines laid down in The IET’s Code of Practice. They already understand the risks and hazards of working with electricity; they should have the technical knowledge to interpret the criteria laid down in this publication and perform the tests as recommended in a safe fashion.

What requires Portable Appliance Testing?

There is a common misconception that it is just equipment that can be plugged in, but it is a little more complex than that. The IET Code of Practice breaks it down into several categories:

• Portable equipment/appliances – Easy to move whilst in operation e.g. Toaster, Kettle, Hair clippers

• Hand-held equipment/appliances – These are portable and by design require the use of direct hand contact e.g. Hair clippers, Drill, 4” angle grinder

• Movable equipment/appliances – this equipment that is similar to the previous two categories but larger/heavier e.g. fridges, mobile air conditioning units

• Stationary equipment/appliances – these are pieces of equipment that are designed not to be moved and generally weigh in excess of 18kg e.g. washing machines, ovens

• Fixed equipment/appliances – as the name suggests these are items that are permanently fixed in place when installed e.g. pillar drill

• Built in equipment/appliances – equipment that is ‘built in’ to a unit or similar e.g. an oven, some types of dishwasher

• IT equipment – e.g. PC’s, laptops, printers, photocopiers

• Extension leads – this includes the reel type and multi socketed types

![]()

If there is a specialist piece of equipment in a workplace, the manufacturer’s guidance should be sought.

Whilst talking about the different types of equipment we also need to look at the different classes of electrical equipment and how they protect the user as these will have ramifications to the visual inspection and any electrical testing to be carried out. There are two methods of protection used to prevent electric shock, they are:

• Basic Protection – prevents the touching of parts that are intentionally live, this can be through the use of insulation or enclosing them to prevent someone coming into contact with them.

• Fault protection – provides protection where any exposed conductive parts of a piece of electrical equipment have become live because of a fault occurring. This can be achieved by the use of double or reinforced insulation or by providing the equipment with an earth path that utilises the automatic disconnection of supply of the electrical installation.

![]()

There are five classes of equipment, but we are only going to look in detail at the three of them that are commonly encountered. The five classes are:

• Class 0

• Class 01

• Class I

• Class II

• Class III

Class 0 and Class 1 are very rarely encountered at present, in the 70’s it effectively became impossible to sell equipment rated as such.

Class I – This type of equipment relies on the basic insulation of live parts to prevent contact with parts that are live under normal conditions. If a fault arose and the outer parts of the equipment became live, the equipment relies on the casing, if it is conductive, being connected to earth via its supply cable and the fixed wiring in the installation. Kettles, desk fans and electric fan heaters are typical examples of Class I equipment.

Class II – This type of equipment relies on either two layers of insulation (double insulation) or insulation equivalent to two layers (reinforced insulation) to protect the user in the event of a fault. Although the equipment is not connected to earth the insulation is of such a design that it will prevent any electricity reaching any part of the equipment that could cause harm. Garden equipment such as electric strimmers and lawn mowers are examples of this type.

Class III – This type of equipment is supplied from what is known as a SELV (Separated Extra Low Voltage) source which will not exceed 50V a.c. Generally Class III equipment will not require PAT testing. Mobile phones and Laptops are examples of Class III equipment. One thing to note with Class III equipment is that although the equipment itself may not require PAT testing, its associated charging equipment may.

What is actually involved in carrying out a Portable Appliance Test?

This can be broken down into 3 areas – Documentation, Visual Inspection & Testing. The final two parts make up what is known as Combined Inspection and Testing

Documentation

Documentation is the often neglected part of a Portable Appliance Test, quite often you’ll see a test performed, a sticker stuck on the piece of equipment and that’s it. Not only does this not really follow the criteria laid down in the IET guide, it also misses a trick when it comes to the ongoing maintenance of the equipment.

The first piece of documentation that is required is a list of all the electrical equipment that is held by the company, this is your electrical equipment register, as a minimum it should list:

• The name/model of the piece of equipment

• An equipment number

• The date upon which the company acquired it

• Its location

• Class of equipment

• The date of its previous PAT test

• The date of the next PAT test

This information will help the person performing the testing to locate and identify the equipment, and track the history of the piece of equipment. This can be useful for determining how frequently the piece of equipment requires testing.

The second document that is required is a combined inspection and test form. This will detail the result of the visual or combined inspection and testing of the piece of equipment. Examples of some of the information required to be in this document are:

• Date of inspection

• Is it being used in the correct environment?

• Was permission obtained to disconnect if required

• The condition of the plug, flexible cable, body of the equipment

• The results of any tests carried out

• Is it safe to use?

• The signature of the person carrying out the work

The final document that is required is the one that is most often neglected, that is a Faulty Equipment and Repair Register. This should contain the following information:

• Date the equipment was taken out of service

• A description of the equipment

• Its equipment number

• Its normal location

• Reason for removal from service

• Just as important as when the item was removed from service is when the item was returned to service and that it is safe to use.

![]()

Visual Inspection

The visual inspection should take place prior to any electrical testing. Although what is inspected will vary from item to item there will be certain things that you will need to check wherever possible. This list is in no way comprehensive but covers the basics.

- Any signs of visible damage to the equipment – this could be cracks in its casing, dents etc

- Any signs of thermal damage to the equipment – are there signs of overheating e.g. discolouration, scorch marks, you may even be able to smell overheating

- Any signs of visible damage to any leads – are there cracks or nicks in the outer sheathing of the cable, can you see the inner layers of insulation, can you see exposed conductor

- Any signs of thermal damage to the leads- are there signs of discolouration or scorch marks

- Any signs of visible damage to the plug – are there cracks, are the pins loose, if the equipment was manufactured after 1994 are the pins sleeved?

- Any signs of thermal damage to the plug – is there discolouration or scorch marks

- Fuse – has the correct size fused been installed?

- Wiring – if the plug is of the re-wireable type it never hurts to check that it has been wired correctly and that the terminations are still tight

- Other things to consider – Is the equipment of the correct type for the environment it is being used in, is the equipment well positioned when in service i.e. no trailing or crushed leads, if the equipment requires clear space around it for ventilation has it got it.

- The results of the visual inspection should be recorded on the Combined Inspection and testing form.

![]()

Testing

Before we look at the details of the tests required, first we will look at the test equipment that is required. There are several choices to make when selecting test equipment for Portable Appliance Testing, but it can be broadly summed up into two types – dedicated PAT testers and separate test equipment.

Dedicated PAT testers come in a variety of types and level of complexities. At the more basic end are simple pass/fail testers that perform the tests and tell the user whether the equipment has passed or failed. The more complex versions will display the results of the test in figures that will need interpreting against the criteria laid down in the IET Code of Practice as well be capable of performing more than the basic required testing.

Separate test equipment can be used to perform Portable Appliance Testing. This can mean either a separate Earth continuity tester and separate insulation resistance tester or a multifunction tester that can perform these two operations. If test equipment of this type is used the earth continuity equipment should have a test current of between 20mA and 200mA, the insulation resistance tester should be capable of applying a test voltage of 500V DC. If using a separate test equipment then a plug adaptor may be required to aid in performing the test.

These are the two main tests required for portable appliance testing. Some purpose built PAT testers are capable of carrying out additional tests such as a touch current test or a load test, they are nice to be able to offer but they are not required.

Earth continuity test

This is the first test to be performed and it can only be used on Class I equipment as this equipment utilises earthing as its fault protection. The purpose of this test is to ensure that that any exposed conductive parts of the equipment (such as the metal casing of a fan heater) that could become live during a fault are connected to the items earth terminal. In the majority of cases, access to the items earth terminal is going to be difficult so testing the earth continuity from the plug on the end of the equipments lead is acceptable. The Code of Practice gives the acceptable readings that an item would need to obtain to pass this test.

Insulation resistance

This test can be carried in several different ways. It is important to note that some electrical equipment especially equipment can be extremely vulnerable to this type of testing and could end up irreparably damaged if not carried out correctly. This test can be carried out on Class I and Class II equipment.

The first method is known as the applied voltage method. It involves connecting the line and neutral conductors together and exposing them to 500V DC and then measuring between them and the earth. The minimum acceptable values can be obtained from the IET Code of Practice.

The second and third methods are known as the earth leakage method and the touch current method. These require the use of a dedicated PAT tester.

Functional testing

Once the piece of equipment has passed the tests the final thing left to do is check that the piece of equipment functions as it should. Some specific PAT testers have a load test function that tests the equipment to ensure it is functioning as designed. The alternative if this facility is unavailable is to connect it the electrical system and check that everything functions as it should.

Once all the testing has been completed the results of the tests and whether the piece of equipment has passed/failed should be recorded on the combined inspection and testing document.

![]()

Labelling

Common practice is to label the piece of equipment detailing the date of the Portable Appliance Testing, when the next test is due and the result of the test. These labels come in a variety of forms and it is worth ensuring that the label your attaching is going to be suitable for the use of the equipment.

A small unobtrusive sticker attached to the side of an office laminator would probably suffice for its day to day to usage without becoming detached. The same sticker attached to the body of an angle grinder will probably either fall off or wear to the point of illegibility. There are lots of alternatives out there, the hardest wearing and longest lasting tend to be the clear plastic connectors that you can snap over a sticker attached to the lead of the piece of electrical equipment or appliance.