What effects do the different types of thermal insulation have on your electrical installation?

BS7671 states that wherever possible, cables should be installed so as to avoid thermal insulation.

However, due to the increasing use of thermal insulation in residential properties, to both reduce the cost of heating bills and to give a good energy performance certificate rating, it is becoming more difficult to do so.

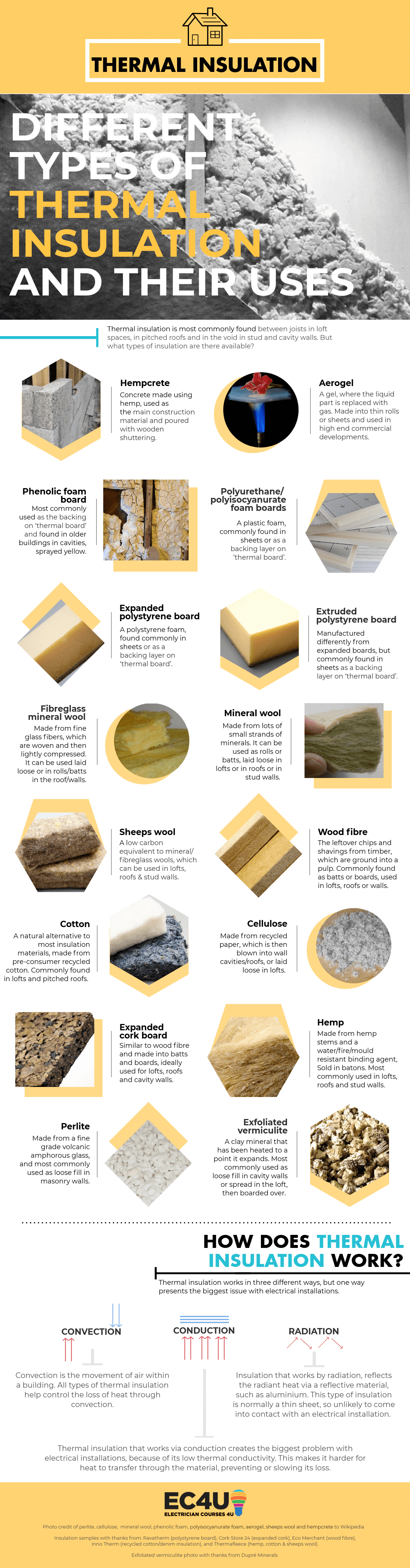

How does thermal insulation work?

Thermal insulation works in three different ways: conduction, convection and radiation.

Any type of the insulation mentioned can prevent heat loss by convection. Convection in this context is the movement of warm air in the building. Warm air will naturally want to rise up through the building, with colder air taking its place. As an example of how thermal insulation can cut down on heat losses due to convection by filling a cavity wall with insulation, the air within that cavity is restricted in its movement, which reduces the amount of convection taking place.

Thermal insulation that works via radiation does so by reflecting radiation, or in this case radiant heat. It does this by being constructed of a material that is reflective, such as aluminium foil.

Of these three different methods, it is thermal insulation that works via conduction that is most problematic for an electrical installation. Thermal insulation that works via conduction does so by having a low thermal conductivity, this makes it harder for heat to transfer through the material, preventing or slowing its loss.

Different materials have different thermal conductivity ratings; this is known as its U-Value. The lower the U-Value, the more efficient the thermal insulation is at retaining heat in the property. For example to achieve a U-Value of 0.15, exfoliated vermiculite would have to be applied to a depth of 430mm, mineral wool however would only need to be 245mm deep to achieve the same value.

Where will I find thermal insulation?

Some of the most common locations for thermal insulation to be installed, especially in properties that were originally built without insulation, are the same places that are commonly run; between joists in loft spaces, in pitched roofs and in the void in stud walls, which is where issues can start to arise.

It is not uncommon to also find thermal insulation bonded to plasterboard, this is known as a thermal board. They are becoming increasingly popular for use in new builds, due to the ease of installation.

PVC cable and polystyrene insulation

The second thing to be aware of is that some particular types of thermal insulation can have a detrimental effect on the PVC insulation used in your common twin and earth cables.

Polystyrene insulation, commonly used as either loose fill or in board form, causes the plasticiser used in the PVC to migrate, in turn causing the premature breakdown of the cable insulation. In the best case, this will cause the need for early replacement of cable due to a shortened service life. In the worst case, this can potentially lead to a fire.

Before a cable is installed, where there is a possibility of contact between PVC and Polystyrene, Polyeurathane or Polyisocyanurate, you should check, if possible, the manufacturer’s data sheet for the thermal insulation product.

If this is not possible, which, depending on the age of the installation may be quite likely, it would be best practice to assume the insulation will cause the migration of plasticiser from the PVC sheath of the cable, resulting in the aforementioned issue.

Thermal insulation comparison chart

The following chart compares several of the more common and emerging insulations currently in use, the thickness to achieve U Value of 0.15 and the effects the insulation will have on the cable

| Material | Description | Thickness to achieve .15 U value | Average available thickness | Effects on cable |

|---|---|---|---|---|

| Hempcrete | Concrete type material made using hemp, mainly used as the main construction material for the building and poured in a similar method to concrete using wooden shuttering. | 80mm | N/A (custom) | Due to the way it is produced and installed, cables will not come into physical contact with them. |

| Aerogel | Aerogel is where the liquid part has been replaced with gas. When used is generally found in thin rolls/sheets, most often found in prestigious commercial developments, although it is becoming more common in domestic applications as the price decreases. | 25mm | 10mm | Due to the way it is produced and installed, cables will not come into physical contact with them. |

| Phenolic foam board | Phenolic foam is often used as the backing on ‘thermal board’, in older installations and it can be found sprayed in cavities. Older installations where the foam has been sprayed will be of a pale yellow colour. | 80mm | <50mm when used as backing | Ensure cable is in contact with thermally conductive surface on one side. |

| Polyurethane foam/polyisocyanurate board and foam | It is a thermo-setting plastic that is produced in a foam form, rather than solid. It can be found as either separate sheets or as a backing layer on ‘thermal board’. | 130mm | <50mm when used as backing | Care must be taken to ensure PVC covered cable does not come into contact with the foam insulation. The insulation can cause migration of the plasticiser used in the manufacture of the PVC cable. As a minimum this will cause premature degradation of the cable insulation and in the worst case can lead to fire. |

| Expanded polystyrene board | It can be found as either separate sheets or as a backing layer on ‘thermal board’. | 215mm | <50mm when used as backing | Care must be taken to ensure PVC covered cable does not come into contact with the foam insulation. The insulation can cause migration of the plasticiser used in the manufacture of the PVC cable. As a minimum this will cause premature degradation of the cable insulation and in the worst case can lead to fire. |

| Extruded polystyrene board | Similar to expanded polystyrene board but manufactured in a different way, can be found as either separate sheets or as a backing layer on ‘thermal board’. | 215mm | <50mm when used as backing | Care must be taken to ensure PVC covered cable does not come into contact with the foam insulation. The insulation can cause migration of the plasticiser used in the manufacture of the PVC cable. As a minimum this will cause premature degradation of the cable insulation and in the worst case can lead to fire. |

| Fibreglass mineral wool (commonly known as fibreglass insulation) | Technically known as glass wool, it is made up of thousands upon thousands of thin strands of glass, and held together with a bonding agent. Commonly found in either rolls or as batts, used in lofts laid loose or in pitched roofs and in stud walls. | 225mm | Generally 100-200mm can be found in 450mm rolls | One of the most commonly encountered types of thermal insulation, often found laid loose in lofts between the joists, with a second layer over the top. While the material itself will not have any physical detrimental effect to cables in the way that a polystyrene based insulation would, it will, depending on thickness, have an effect on the current carrying capacity of your cables. Wherever possible ensure that your cables are in contact with a thermally conductive surface on one side. |

| Mineral wool | Mineral wool is made from lots of small strands of various types of minerals, which have been melted at extremely high temperatures and, while molten, are spun in a similar way to candy floss to produce the strands. Similar to Fibreglass mineral wool, it can be found in either rolls or batts, used in lofts laid loose or in pitched roofs and in stud walls | 245mm | Generally 100-200mm can be found in 450mm rolls | One of the most commonly encountered types of thermal insulation, often found laid loose in lofts between the joists, with a second layer over the top. While the material itself will not have any physical detrimental effect to cables in the way that a polystyrene based insulation would, it will, depending on thickness, have an effect on the current carrying capacity of your cables. Wherever possible ensure that your cables are in contact with a thermally conductive surface on one side. |

| Sheep’s wool | Low carbon/carbon neutral equivalent to mineral/fibreglass wools, most often found as rolls, used in lofts, pitched roofs and stud walls. | 245mm | Generally 100-200mm can be found in 450mm rolls | Used in a similar way to fibreglass and mineral wool insulation. It is nowhere near as common, but it is becoming increasingly popular due to its green credentials. Similar to fibreglass/mineral insulation, it will cause no damage to the material of your cable, but depending on the thickness and the route the cable is run, could have an effect on the cables current carrying capacity, again, wherever possible, ensure your cable is run with one side in contact with a thermally conductive surface. |

| Wood fibre | The leftover chips and shavings from timber processing are ground down into a pulp, mixed with water and a binder, it is then cured and cut to shape to make wood fibre insulation. Most often found in batts or boards, used in lofts, pitched roofs and cavity walls | 245mm | 30-240mm | Due to the rigid nature of the material will generally be easier to avoid with your cables than a looser thermal insulation. The potential for an issue arises where it has been used as insulation in internal stud walls. If cables need to run through it, ensure one side of the cable is in contact with a thermally conductive surface. |

| Cotton | Cotton insulation is generally made from pre-consumer recycled cotton, its considered a good ‘natural’ alternative to the most common type of insulations, generally found in lofts and pitched roofs | 245mm | 90mm – 215mm | Used in a similar way to fibreglass and mineral wool insulation It is nowhere near as common, but it is becoming increasingly popular due to its green credentials. Similar to fibreglass/mineral insulation, it will cause no damage to the material of your cable, but depending on the thickness and the route the cable is run, could have an effect on the cables current carrying capacity, again, wherever possible, ensure your cable is run with one side in contact with a thermally conductive surface. |

| Cellulose | Recycled paper, which is then blown into cavities, suspended behind boards in pitched roofs or laid loose in lofts. | 250mm | Loose fill | Generally applied in two ways, either blown into cavities or spread loose in loft spaces between and over rafters. The cellulose is treated with an anti mould and anti damp compound. Due to its relatively low cost compared to other forms of insulation is becoming increasingly popular. As the individual pieces slowly settle and compact over time the resulting loss of air space causes its thermal efficiency to decrease. The material itself has no detrimental effects to the PVC insulation in a standard twin and earth cable. It is best however to ensure that if your cables are covered in this insulation that one side is in contact with a thermally conductive material. |

| Expanded cork board | Similar to wood fibre, it can be found in both batts and boards, used in lofts, pitched roofs and cavity walls. | 275mm | 20 – 100mm | Due to the rigid nature of the material, it will generally be easier to avoid with your cables than a looser thermal insulation. The potential for an issue arises where it has been used as insulation in internal stud walls. If cables need to run through it, ensure one side of the cable is in contact with a thermally conductive surface. |

| Hemp | Found as solid batons, consisting of hemp stems and a fire/water/mould resistant binding agent. | 280mm | 50 – 250mm | Due to the rigid nature of the material, it will generally be easier to avoid with your cables than a looser thermal insulation. The potential for an issue arises where it has been used as insulation in internal stud walls. If cables need to run through it, ensure one side of the cable is in contact with a thermally conductive surface. |

| Perlite | Fine grade volcanic amphorous glass, used as a loose fill in masonry walls. | 285mm | Loose fill | Not to be confused with exfoliated vermiculite which is used in a similar manner, Perlite can be used to fill the cavity in walls. However, will more likely be encountered as a loose layer in lofts, often in combination with a board type insulation fixed over the top. The material has no detrimental effect to the PVC insulation used by normal twin and earth cable, however if your cables are going to be covered in perlite, ensure that one side of the cable is in contact with a thermally conductive surface. |

| Exfoliated vermiculite | A clay mineral that is heated to the point it expands. As well as insulation other common uses are as a substrate for animals, or as an alternative/additive to soils for growing plants. Vermiculite is a Is found as a loose fill in cavity walls,or spread in lofts, where it is quite often then boarded over. | 430mm | Loose fill | Not to be confused with perlite, which is used in a similar manner, exfoliated vermiculite can be used to fill the cavity in walls. But it will more likely be encountered as a loose layer in lofts, often in combination with a board type insulation fixed over the top. The material has no detrimental effect to the PVC insulation of twin and earth cable, however if your cables are going to be covered by the material, ensure that one side of the cable is in contact with a thermally conductive surface. |

In summary

As you can see, there are a wide variety of different types of insulation out there. The chart above is by no means comprehensive, but covers some of the more common types that you are likely to encounter in a domestic setting. The key thing to remember is that if you have no choice but to run your cables either in, or on, thermal insulation, the cable must be de-rated in accordance with BS7671.

As previously stated, it is essential that PVC insulated cables such as your common twin and earth must not be run in direct contact with any form of polystyrene insulation. We would suggest that if your cables do need to be run in close proximity to this type of insulation, that they are protected by some form of containment such as plastic conduit.